100% Irish Owned

How to Choose the Right Air Compressor?

How to Choose the Right Air Compressor?

The decision on the air compressor which you are purchasing is a very important one. You need to ensure the machine you purchase is up to the task in which it is to be used for. An undersized air compressor may start the job but it will either fail in use or fail to complete the task at hand.

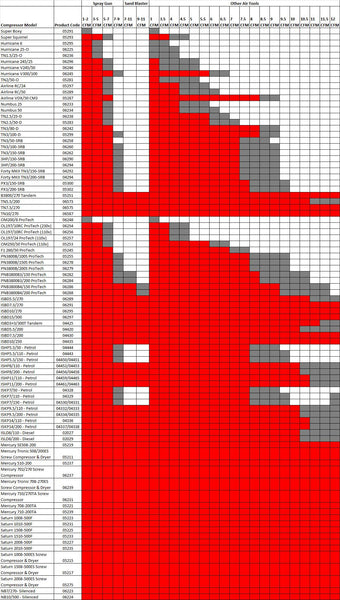

When choosing your air compressor the first thing to consider is the free air delivery (FAD) output. Simply choose the air tools which you will require the air compressor to power; each air tool will have a CFM rating. This CFM rating must be equal to or higher than the FAD of the compressor in order for them to be compatible. It is good practice to check all air tools to be used with the compressor before making a final decision. Please see our air tool/ air compressor compatibility table below.

The second thing to consider is the air receiver size, some tasks and/or air tools require more air supply than others. This air receiver supplies the air to the air tool so needs to be the correct size for the task it’s required for. Certain jobs such as periods of sanding or spraying requires much more air than a short sharp blast of an air gun so this should be reflected when choosing the correct air receiver size.

Other compressor tips;

- When sanding or spraying ensure the air compressor is as far away as possible to prolongue the life of your machine.

- Compressors should have a maximum of 10 starts per hour.

- Piston compressors need periods of rest to cool down.

Understanding Key Terms

The biggest problem when shopping for air compressors is the sheer amount of jargon that will be thrown at you when you compare specifications. Air compressors aren’t particularly complex machines, but their effectiveness and efficiency are measured in ways that don’t apply to a lot of other machines.

Here are some the key terms you should be familiar with when deciding on your air compressor:

CFM

CFM stands for cubic feet per minute, and is the basic measuring tool that tells you how fast a compressor can supply air. Basically, if a tool needs more air than the compressor can supply, there will be a lot of downtime in using the tool as it waits for the compressor to supply enough air to it. The more powerful the tool, the higher the CFM will need to be to operate it properly.

PSI

For home handyman tools, pounds per square inch, or PSI, isn’t relevant. For industrial applications, however, it is important. A higher max PSI also allows for a smaller tank to hold more air and perform with the effectiveness of a larger tank.

Decibels (dB)

Decibels, or dB, is the rating for the noise that a machine makes, and while you might dismiss this number as a comfort factor for those using it rather than a major consideration, it’s actually very important. Air compressors can be very loud, so do take this into consideration if you are thinking of locating the compressor in a similar area where you will be working.